When jewelers first see a fully packed JewelsPrint casting tree, the reaction we hear most is almost always the same:

“This is incredible… but how can I possibly print this on a resin printer?”

We completely understand that skepticism. We are looking at dozens of jewelry models, tightly packed, rising into a tall, industrial-scale structure. It is a new frontier for our industry. Because JewelsPrint was the first to develop a way to generate a complete, optimized 3D-printed casting tree, we knew we had to answer the challenges that traditional slicers simply weren’t built to handle, particularly regarding effective jewelry 3d support.

As I spoke with manufacturers, I kept hearing the same valid concerns:

- Height & Volume: How does this tall structure fit within a standard resin printer?

- Print Time: Does a tree this tall take all day to print?

- Support Placement: How can you fit proper jewelry 3d support structures between such tightly packed objects?

- Material Stability: How do you prevent tall trees from swaying or “noodling” when using soft, high-wax castable resins?

- Post-Processing: How can I clean models in the center of the tree without damaging delicate prongs?

- Reliability: How is stability guaranteed without flooding the tree with resin-wasting supports?

At JewelsPrint,a 3d printed jewelry casting tree solution ,we didn’t just build a nesting tool; we developed a proprietary Smart Jewelry 3D Support System. By shifting from “manual pillar placement” to “automated path finding,” we have made high-density, industrial-scale printing not just possible—but the most efficient way to manufacture jewelry. Here is how our system works.

🎧 Listen to the Podcast Prefer listening over reading? You can now tune in to the audio version of this article. Listen to the full episode below to discover how our advanced jewelry 3d support system is revolutionizing industrial printing—perfect for learning while you work at the bench.

To give you an immediate understanding of our technology, the table below outlines the key JewelsPrint innovations detailed in this article.

| The Challenge | Our Smart Solution | Your Manufacturing Benefit |

| Z-Height & Long Print Times | Modular Stack Tree | Fits any printer; prints much faster side-by-side. |

| Support Scars & Resin Waste | Smart Pathfinding ($A^*$) | Supports “weave” through gaps; minimizes resin consumption. |

| “Soft” Castable Resins | Smart Density Calculation | Prevents swaying and distortion in high-wax materials. |

| Resin Waste on Sprues | 20-30° Sprue Angle | No extra scaffolding; Hydrodynamic laminar flow reduces porosity. |

| Failed Prints / Islands | Voxel-Based Detection | 100% reliability for complex organic geometries. |

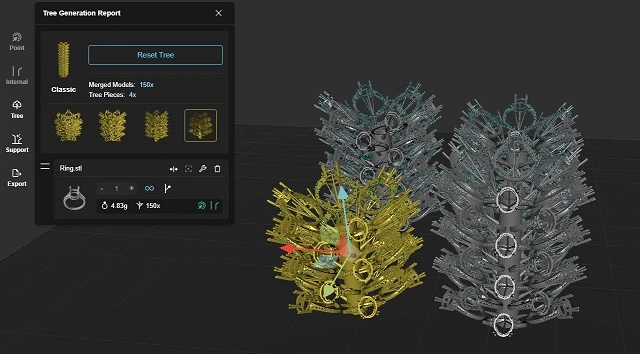

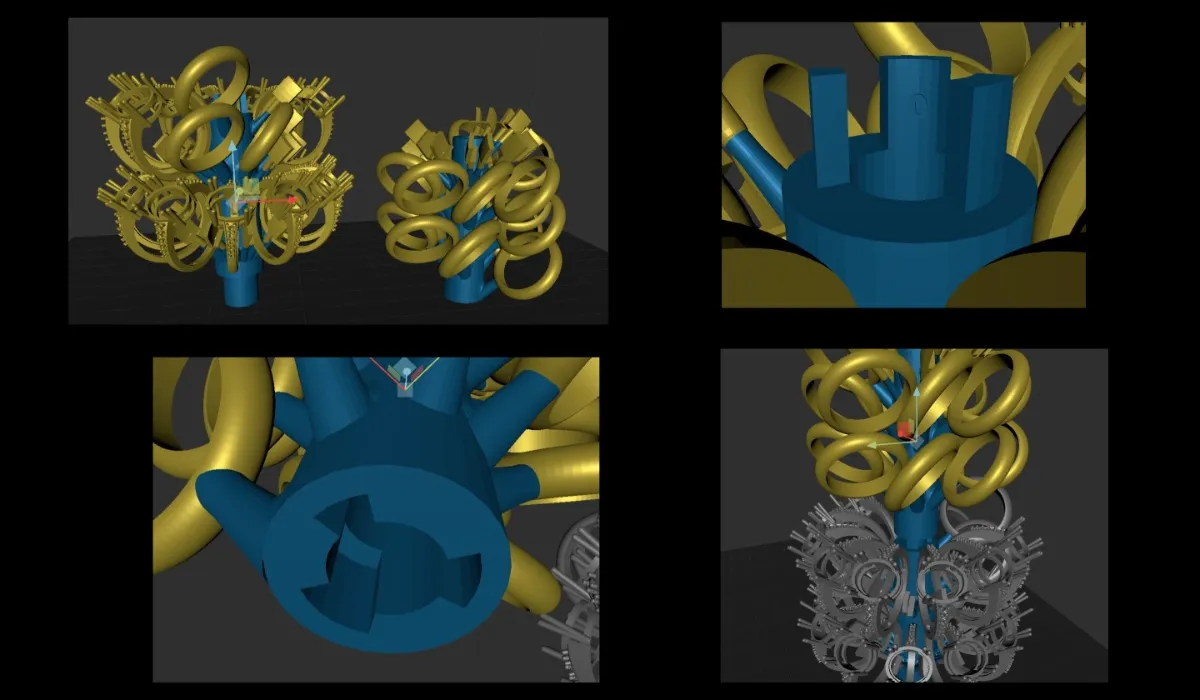

The “Modular Stack” Casting Tree: Solving Height, Cleaning, and Print Time

The most immediate hurdle we addressed was the physical limit of the printer. Most high-resolution resin printers have a limited Z-axis, and a dense, single-piece tree is a nightmare to clean without a sophisticated jewelry 3d support strategy.

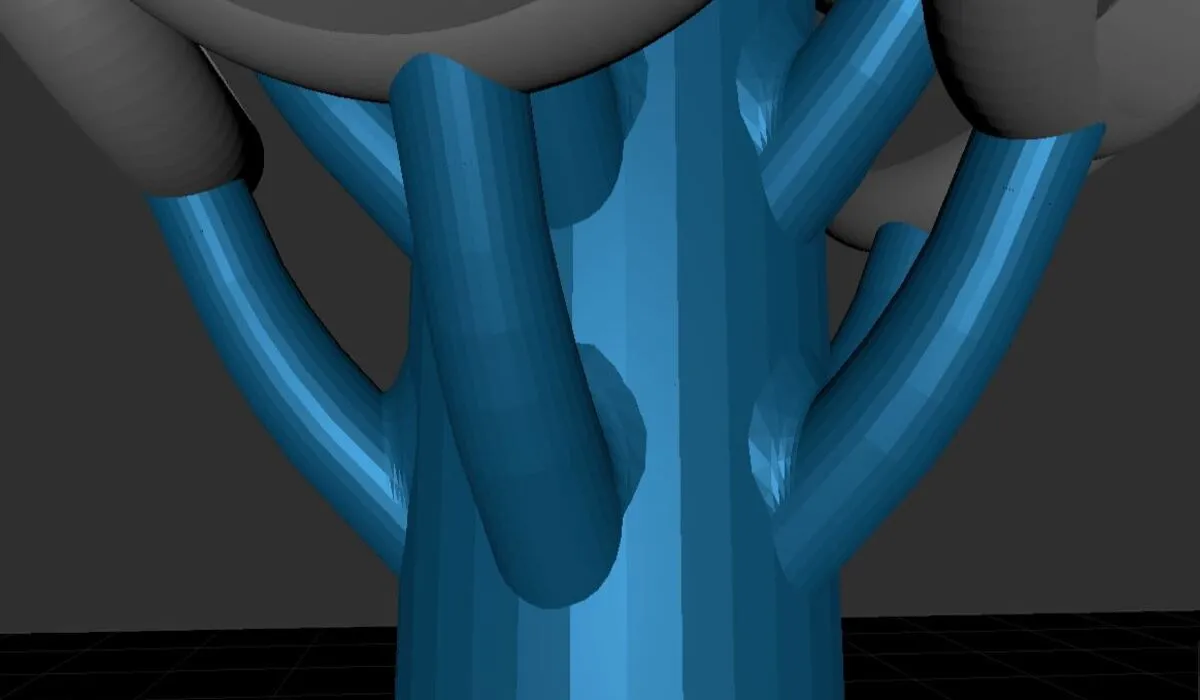

Our solution is the Modular Stack Casting Tree system.

- Breaking the Height Barrier: The software intelligently segments the main sprue (the trunk) into interlocking parts. These sections print independently as a series of nested components, allowing you to produce industrial-sized loads on the hardware you already own.

- Slashing Print Time: Since resin printing time is determined by height, we realized that by splitting a tall tree into shorter segments placed side-by-side on the build plate, we could significantly reduce total print time. Printing three short segments simultaneously is much faster than printing one tall tree.

- 360-Degree Access: We wanted to make cleaning effortless. Because the tree is disassembled during post-processing, you have open access to the center of every layer. You can clean models and remove jewelry 3d support tips with total visibility before snapping the tree together using our precision-engineered mechanical locks.

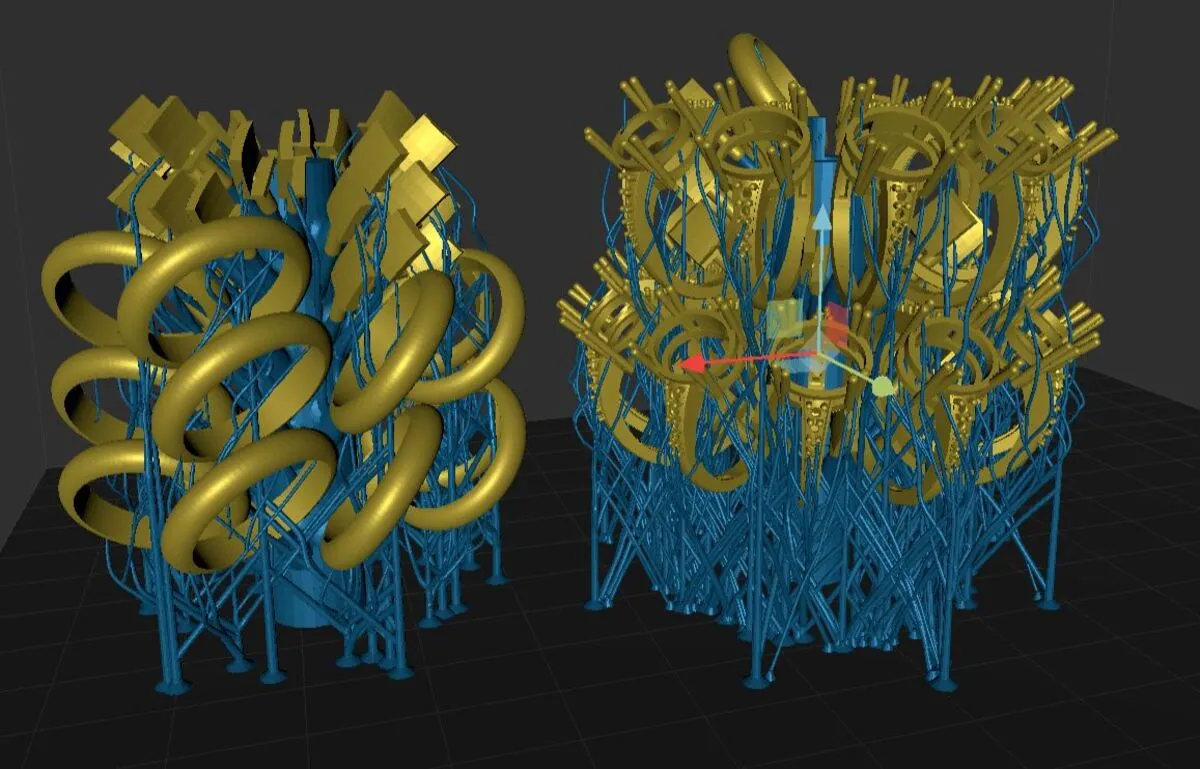

Intelligent Path finding: Curved Supports and Smart “Body-to-Body”

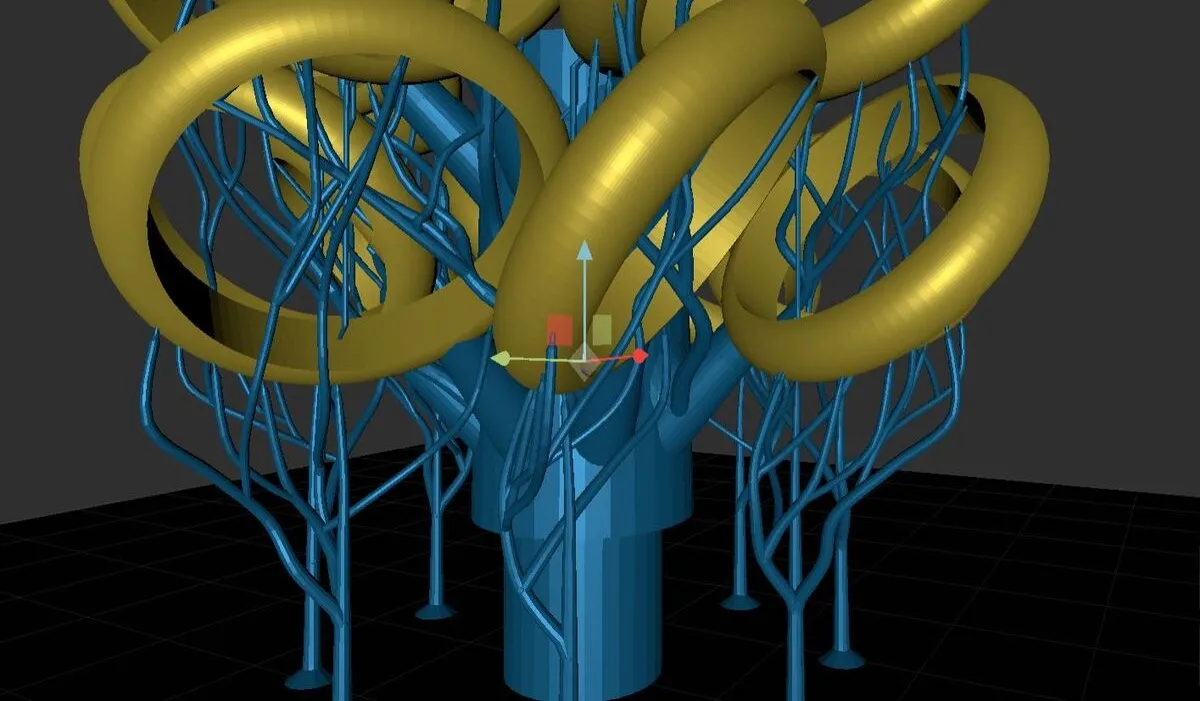

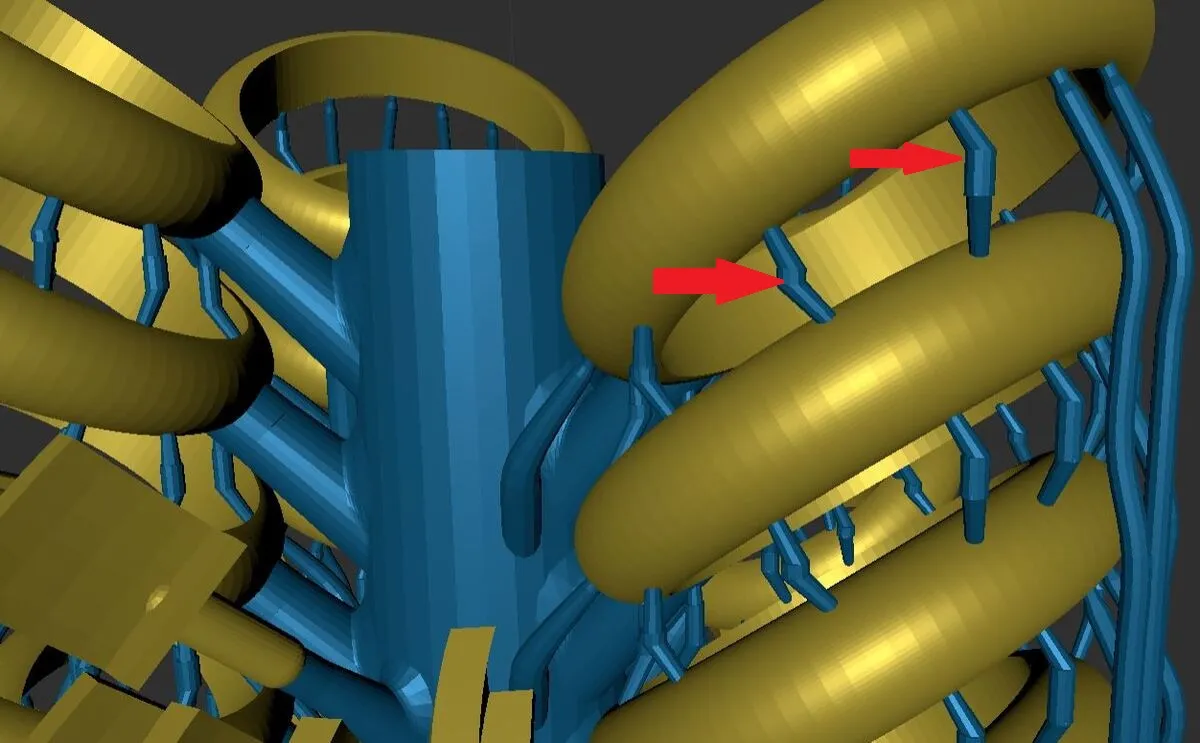

Traditional supports are “blind” vertical pillars that often collide with models in a dense tree. We utilized advanced Voxel-Based Analysis and Smart Path finding ($A^*$ Algorithm)—the same precision technology used in GPS navigation—to navigate the complex “forest” of jewelry.

- Navigation for Your Jewelry 3D Support: Our algorithm treats the empty space between models like a map. It “drives” supports through the narrowest gaps using Bézier and Catmull-Rom spline interpolation. This creates smooth, curved paths that find the most direct, efficient route to the base plate.

- Reduced Resin Usage: By finding the shortest path through these gaps, the software avoids unnecessary pillar length. This optimizes your jewelry 3d support usage, slashing resin waste while maintaining rock-solid stability.

- The Priority of Cleanliness: Our primary goal for the algorithm is to avoid touching the jewelry. However, in extremely dense areas where no clear path to the base exists, we strategically set Body-to-Body supports.

- A Strategic Choice: We designed these Body-to-Body structures to be strong for the print, but they can also remain for casting to act as metal flow auxiliary channels. If your priority is easier cleaning, you can simply increase the “Min Object Gap” (Padding) in the menu to give the path finding algorithm even wider “corridors.”

The 20-30 Degree Rule: Zero Resin Waste

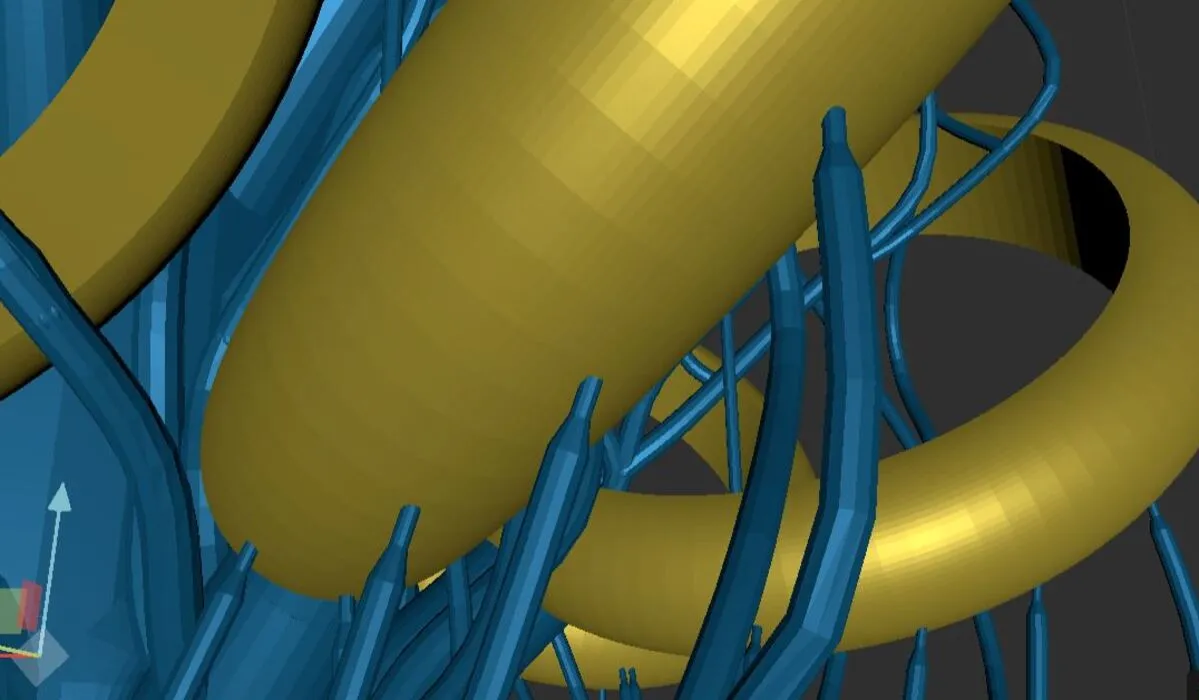

Resin is expensive. We saw that traditional sprues set at 45 or 90 degrees were inefficient because they required their own extra jewelry 3d support just to keep from sagging.

- Self-Supporting Geometry: JewelsPrint optimizes the sprue angle to a steep 20 to 30 degrees. At this angle, the sprue acts as a ramp that supports itself layer-by-layer without extra scaffolding.

- Zero Waste & Better Castings: By using curved splines instead of straight lines, we eliminate extra waste and create a smooth, hydrodynamic path for the molten metal. This promotes laminar flow, which significantly reduces turbulence and air entrapment—the leading causes of porosity in your final gold or silver cast.

Precision Detection and Load Calculation

To ensure a 100% success rate on tall, heavy trees, we built a “one-click” architecture that handles the complex math in the background. This is especially vital when working with castable resins, which have a high wax content and are often “softer” or more prone to swaying, requiring highly specific jewelry 3d support configurations.

- Island & Overhang Detection: The system slices the model at regular intervals to find disconnected regions (islands) that would otherwise cause a print failure.

- Accounting for Castable Resin Physics: Because professional castable resins have a high wax content, they often have lower structural “green strength” compared to standard resins. This can cause tall trees to sway or bend during the printing process. We’ve engineered our supports with wider bases and Load-Balanced Bracing. While the user maintains control over the support diameter, our software calculates the optimal jewelry 3d support density and placement based on the cumulative weight and structure of the tree. This ensures the structure remains rigid and stable, even when using “loose” wax-based materials.

- Variable Radius Pillars with Customizable Tips: We engineered our supports with wider bases for stability, tapering down to microscopic contact points. While our default settings are optimized for a clean break, you have full control over the tip diameter from the configuration menu. You can go even lower than 0.3mm for ultra-delicate pieces or increase it for heavier models. This ensures the tree remains rock-solid during the entire print, but the jewelry 3d support snaps off by hand, leaving almost no mark on your delicate surfaces.

- Intelligent Merging for Resin Economy: When multiple supports follow similar paths toward the base, our software automatically merges them into a single, reinforced trunk. This Intelligent Merging minimizes the total surface area and volume of resin used without compromising the structural integrity needed to support a heavy, industrial tree.